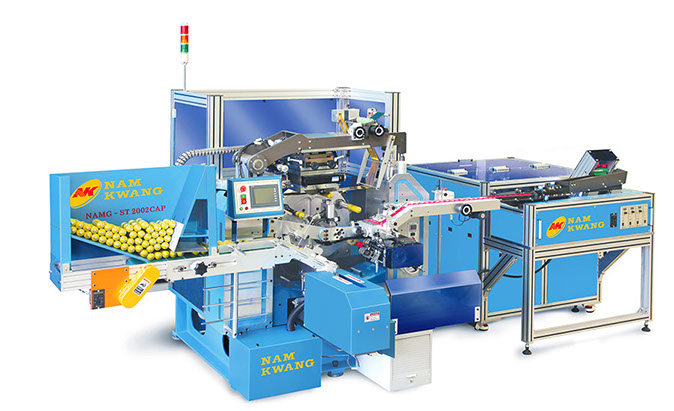

Hot Stamping & Capping Machine

Specification

・ Perfect adaptability for connecting with

head injection machine

・ High working efficiency and low cost by dual function

of stamping and capping.

・ 편리성, 신속성, 안정성 등 소량 다품종 및 대량생산에 적합

・ 금박과 캡핑을 동시에 할 수 있어 작업 효율성 증대

・ 사출된 튜브와 슬리브 튜브에 직접 금박이 가능하여 생산비 절감

Model

Application

Tube Diameter

Production Capacity

Power Consumption

: NAMG - ST - 2002CAP

: Cosmetic Tube, Tooth paste tube

: ∅16~60mm

: 70pieces/Min (for Capping)

30pieces/Min (for Stamping)

: 220V / 380V, 50Hz / 60Hz, 8kW

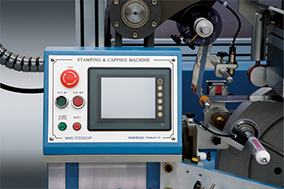

- PLC & Precision control by servo motor

- Touch screen

- High precise position control by I-mark sensing

- Advanced technology of position control of

tube without I-mark

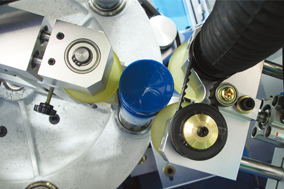

- Precision bi-axial(X-Y) position control (Patented)

- Convenient and rapid working condition by the

innovative feeding method

(horizontally cap feeding and capping under

standing of cap)

- Reduce the setting time of working condition

- Adjustable torque control to meet

requirements (Patented)

NamKwang PNS

Copyright © 2000 NamKwang PNS Co.,Ltd All rights Reserved

TEL +82 31 366 5630 / FAX +82 31 366 5632 / info@namkwangpns.co.kr